Manufacturing Jobs: What They Really Involve and How They Keep Cars on the Road

When you think about how your car gets built, manufacturing jobs, paid roles in factories where vehicles and parts are assembled, tested, and finished. Also known as automotive manufacturing, these positions are the backbone of every vehicle you see on the street. Without them, even the most advanced electric car would just be a sketch on a screen. These aren’t just assembly line gigs—they’re skilled trades that require precision, training, and constant adaptation as technology evolves.

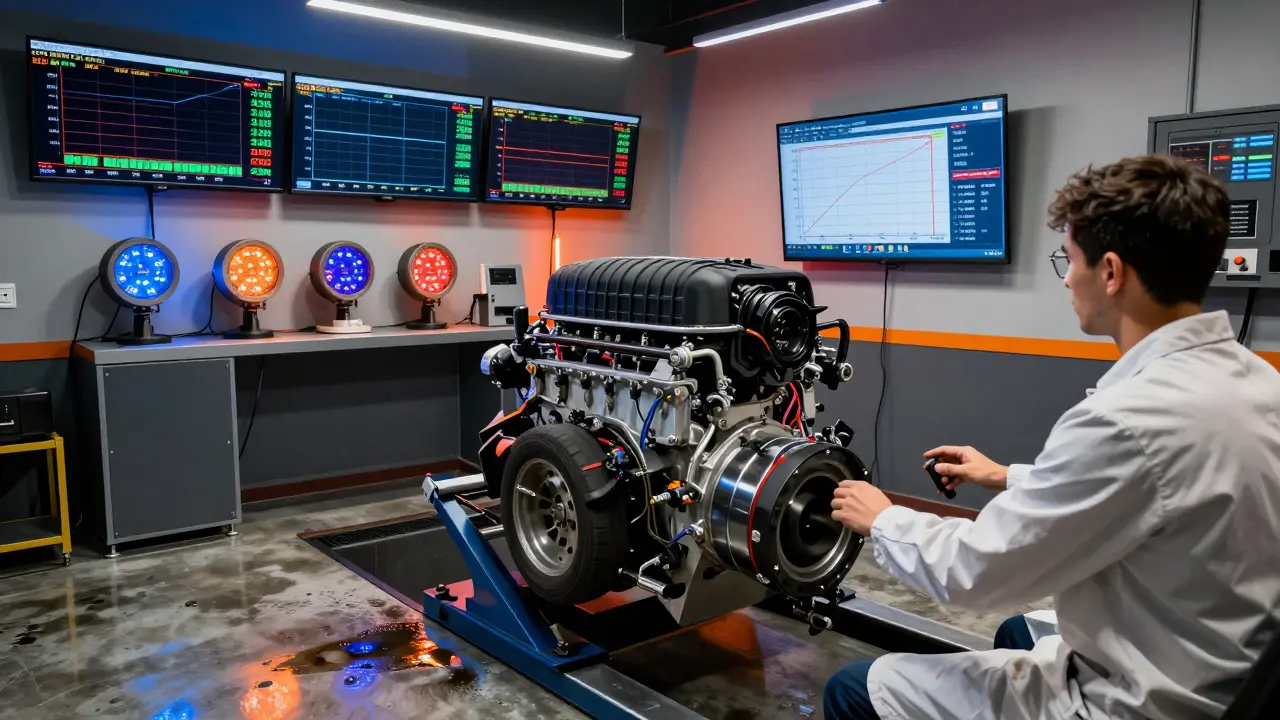

Most automotive manufacturing, the process of building cars and their components in large-scale industrial facilities starts with raw materials—steel, aluminum, plastic—and ends with a fully functional vehicle. It’s not just about tightening bolts. Workers now handle robotics, quality control sensors, and digital workstations that track every part’s history. car parts production, the specialized manufacturing of individual components like transmissions, brakes, and suspension parts happens in separate facilities, often run by suppliers who work directly with big automakers. These parts don’t just show up—they’re engineered, tested, and shipped with exacting standards. And when a recall happens? It’s often traced back to a single batch made in one of these plants.

Manufacturing jobs don’t just build cars—they keep them running long after they leave the lot. The assembly line jobs, repetitive but highly coordinated tasks performed in sequence to assemble vehicles you see in documentaries? They’re still around, but now they’re paired with AI-assisted tools and real-time diagnostics. Workers check torque on engine mounts, verify weld integrity with cameras, and scan QR codes to track every bolt used. This isn’t factory work from the 1980s. It’s high-tech, high-stakes, and essential. Even as electric vehicles rise, the need for skilled labor hasn’t gone away—it’s shifted. Battery packs need assembly. Motors need winding. Cooling systems need sealing. The same people who once built V8 engines now build battery modules.

What you might not realize is how many of the car parts you read about here—truck bed liners, transmission tuning kits, motorcycle armor—started as raw material in a factory somewhere. Someone had to press the metal, mold the plastic, test the fit, and sign off on the quality. These jobs aren’t glamorous, but they’re the reason your brakes don’t fail and your headlights stay aligned. They’re the reason you can buy a replacement alternator and know it’ll work right the first time.

Below, you’ll find real stories and guides that connect the dots between what happens in these factories and what you experience behind the wheel. Whether it’s how a recall affects production, why quality parts cost more, or how new tech is changing the shop floor—this collection shows you the hidden world that keeps your car alive.

How Automobiles Drive Economic Growth Around the World

- 9 Comments

- Nov, 1 2025

Automobiles drive economic growth by creating millions of jobs, fueling supply chains, funding public services, and enabling mobility. From manufacturing to exports, cars shape national economies and lift communities worldwide.