Most people think transmission tuning is about making your car shift harder or faster. That’s not it. Real transmission tuning is about balance-getting the right shift points, setting proper line pressure, and making sure your transmission lasts. Do it wrong, and you’ll burn out clutches, shred bands, or fry the valve body. Do it right, and your transmission runs smoother, pulls stronger, and lasts tens of thousands more miles. This isn’t magic. It’s math, pressure curves, and understanding how your transmission actually works under load.

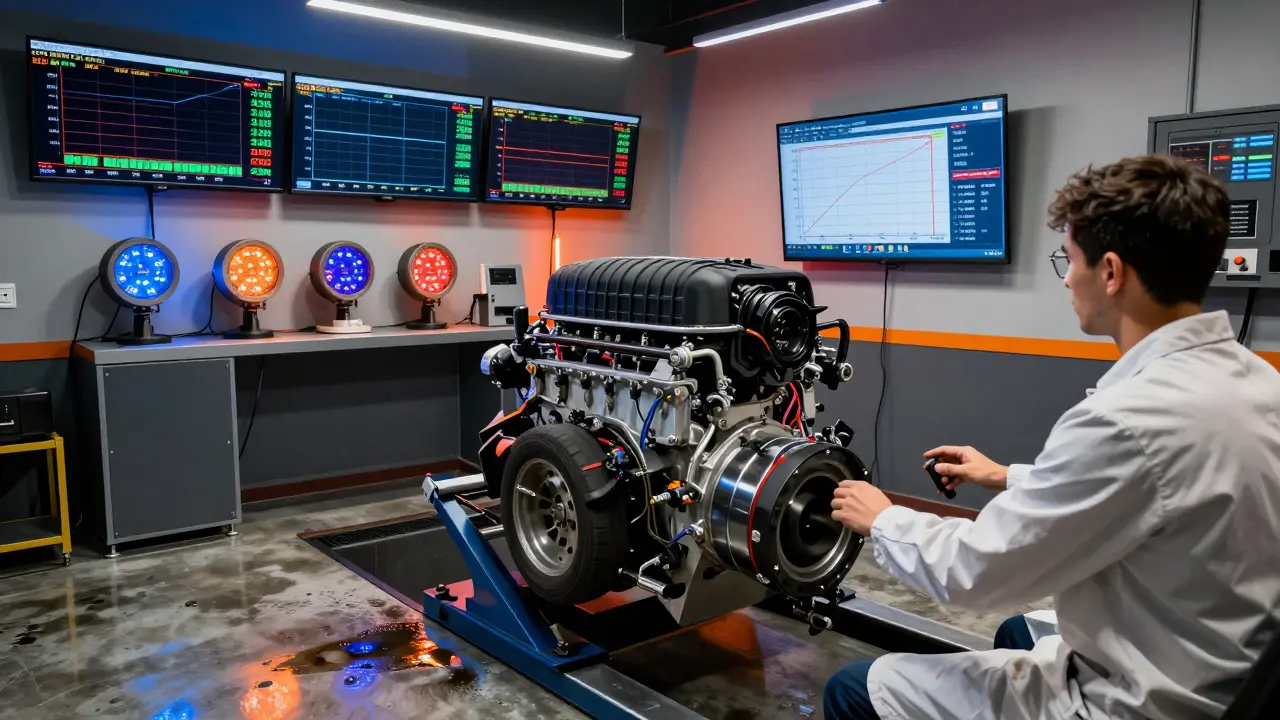

What Shift Points Really Mean

Shift points aren’t just when the transmission changes gears. They’re the exact engine RPM and vehicle speed at which the transmission decides to upshift or downshift. Factory settings are designed for fuel economy and smoothness, not performance or towing. If you’ve ever felt your truck lug in 4th gear climbing a hill, or your sports car hesitating before downshifting on a backroad, that’s a shift point problem.

Most aftermarket tuners raise shift points to keep the engine in its power band. But pushing shift points too high-say, past 6,800 RPM in a 6L80 transmission-creates massive stress. The clutches don’t have time to fully engage. The gear teeth slam together. Heat builds up fast. A 2023 study by the Automotive Transmission Institute found that transmissions shifted above 6,500 RPM under load failed 47% faster than those shifted at 5,800 RPM, even with the same fluid and cooling.

The sweet spot? Match shift points to your engine’s torque curve. If your modified 5.3L V8 makes peak torque at 4,400 RPM, aim to upshift just after that-around 4,800 to 5,000 RPM. That’s when you’re pulling hardest and the engine still has momentum. Downshifts should happen early enough to keep the engine from lugging but not so early that you’re constantly shifting on the highway. A good rule: if you’re shifting more than twice per mile on a steady road, you’re overdoing it.

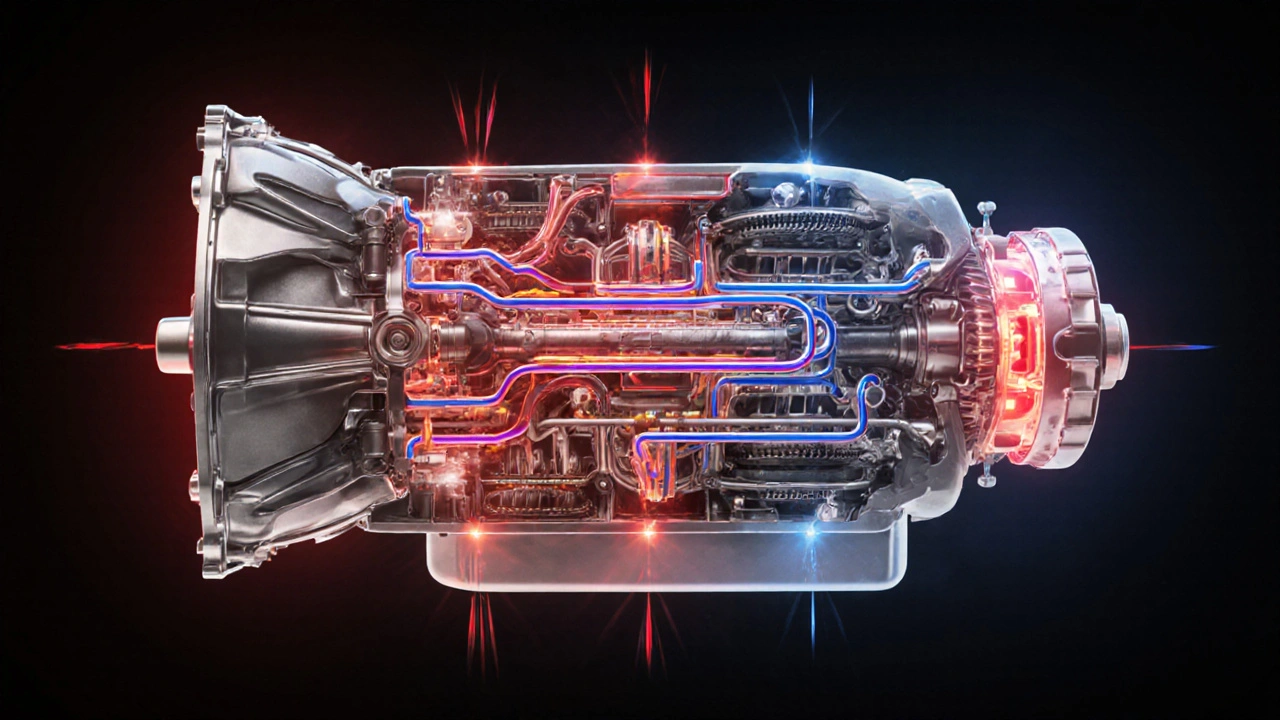

Line Pressure: The Hidden Killer

Line pressure is the hydraulic force that clamps the transmission’s clutches and bands together. Too low, and the clutches slip. Too high, and you overload seals, valves, and even the case itself. Factory line pressure is set for average driving conditions. When you add horsepower, tow heavy loads, or run bigger tires, that pressure needs to change.

Many tuners crank line pressure up to 200+ psi thinking it’ll make shifts firmer. But a 6L80 transmission’s factory max is around 150 psi. Pushing it to 200 psi doesn’t make it stronger-it makes it brittle. The valve body’s solenoids weren’t designed for that kind of stress. Seals blow. Pressure sensors fail. The transmission starts hunting for gears or slipping under light throttle.

Real tuning adjusts pressure based on load and RPM. For example, a truck towing 8,000 lbs needs higher pressure in 3rd and 4th gear under 2,000 RPM, but lower pressure in 5th and 6th at cruising speed to reduce heat. Modern tuners like HP Tuners and EFI Live let you create pressure maps that change dynamically. Set it so pressure increases gradually with engine load, not just with RPM. A 10% pressure increase over stock at full throttle is usually enough. More than that? You’re asking for trouble.

How Heat Kills Transmissions

Heat is the #1 killer of automatic transmissions. Every time a clutch slips-even a little-it generates heat. That heat breaks down transmission fluid. Fluid that’s over 200°F starts to oxidize. At 250°F, it turns to varnish. At 300°F, the seals swell and the clutches glaze over. A transmission running at 300°F for more than 10 minutes can fail within 500 miles.

Transmission tuning affects heat in three ways: shift timing, line pressure, and torque converter lockup. Late shifts mean more slipping. High pressure causes more friction. Lockup that engages too early or too late creates slippage in the converter.

The fix? Set lockup to engage at 40 mph or higher, not 25 mph. That keeps the converter from overheating during city driving. Use a transmission temperature gauge. If you’re regularly hitting 220°F on the highway, you need a larger cooler or a deeper pan. Don’t rely on the factory cooler-it’s designed for a stock 300-hp engine, not your 500-hp build.

Fluid Matters More Than You Think

You can have perfect shift points and ideal line pressure, but if you’re using the wrong fluid, you’re wasting your time. Dexron VI, Mercon LV, ATF+4-each fluid has different viscosity, friction modifiers, and thermal stability. Using the wrong one can cause slipping, delayed engagement, or premature wear.

For modified transmissions, synthetic fluids like Royal Purple MaxATF or Amsoil Signature Series offer better heat resistance and shear stability. But don’t just swap fluids. Flush the system completely. Old fluid mixed with new creates unpredictable friction. A 2024 test by Transmission Dynamics Lab showed that even 15% contamination of old fluid reduced clutch life by 32%.

Also, change your fluid every 30,000 miles if you’re tuning your transmission. Factory intervals are 100,000 miles-meant for gentle highway driving. If you’re towing, racing, or hauling, treat it like engine oil: change it often.

What Happens When You Skip the Basics

Too many people skip the foundation and go straight to the tuner. They buy a $500 flash tune, plug it in, and expect miracles. Then their transmission starts slipping after 5,000 miles. They blame the tuner. But the problem was never the tune-it was the worn clutches, the old fluid, the clogged filter, or the cracked cooler line.

Before you tune:

- Check your transmission fluid. Is it dark, burnt-smelling, or gritty?

- Inspect the pan. Any metal flakes? That’s clutch material breaking down.

- Test your cooler. Is it clogged? Is the flow strong?

- Are your mounts worn? Bad mounts cause shock loads that damage internal parts.

- Have you replaced the filter? A clogged filter starves the pump and drops pressure.

Fix these first. Then tune. A clean, healthy transmission with a good tune will last 150,000+ miles. A dirty one with a perfect tune? It’ll die before you hit 60,000.

Real-World Tuning Scenarios

Let’s say you’ve got a 2018 Silverado with a 6L80, 5.3L engine, and you added a cold air intake, headers, and a tune for 450 hp. You tow 6,000 lbs every weekend.

Here’s what you should do:

- Replace the fluid and filter with synthetic ATF.

- Install a 20,000 BTU transmission cooler.

- Set shift points to upshift at 5,000 RPM under load, downshift at 3,800 RPM when accelerating.

- Set line pressure to 145 psi at full throttle, 120 psi at cruise.

- Enable torque converter lockup at 45 mph and hold it until 20 mph.

- Monitor temps. If you hit 220°F regularly, add a fan to the cooler.

Or you’ve got a 2020 Mustang with a 10R80 transmission and 600 hp. You want quicker shifts without sacrificing daily drivability.

- Use a lower line pressure-135 psi max-to reduce stress on the complex clutch packs.

- Set shift points to 6,200 RPM for upshifts, but only in Sport mode. Keep stock shift points in Normal.

- Delay lockup until 50 mph to keep the converter helping with traction.

- Install a transmission temperature sensor and an alert on your dash.

Longevity Is the Goal, Not Power

Transmission tuning isn’t about making your car faster. It’s about making your transmission smarter. A well-tuned transmission shifts with purpose. It holds gears when you need them. It lets go when it’s safe. It doesn’t fight you. It doesn’t overheat. It doesn’t break.

Most people tune for the thrill. The best tuners tune for the long haul. The guy who shifts at 5,200 RPM, runs 140 psi, and changes fluid every 30,000 miles? His transmission is still going strong at 220,000 miles. The guy who cranked everything to max and never checked the fluid? His transmission died at 55,000.

There’s no magic setting. Every car is different. Every engine is different. But the rules don’t change: balance pressure, time shifts to your torque curve, keep it cool, and keep it clean. Do that, and your transmission won’t just survive-it’ll outlast your next car.

Can I tune my transmission without a professional tuner?

Yes, but only if you have the right tools and knowledge. Devices like HP Tuners, EFI Live, or Diablosport allow you to adjust shift points and line pressure yourself. But if you don’t understand how transmission hydraulics work, you risk damaging it. Start with conservative changes-no more than 10% over stock-and monitor temperatures and shift quality. If you’re unsure, hire a professional. A bad tune costs more than a good tune.

Does transmission tuning void my warranty?

Yes, in most cases. Manufacturers can detect tuning through diagnostic logs. Even if you restore stock settings, some data remains. If your transmission fails and they find a tune in the history, they’ll deny the claim. Some aftermarket parts come with their own warranties, but they rarely cover transmission damage caused by tuning. Always check your warranty terms before you flash.

How do I know if my transmission is overheating?

Signs include slipping under load, delayed engagement, burning smell, or the transmission warning light. The best way to know? Install a transmission temperature gauge. Normal operating range is 160-200°F. Above 220°F is dangerous. Above 250°F is critical. If you’re regularly hitting 230°F, you need a bigger cooler or a deeper pan.

What’s the best transmission fluid for tuned transmissions?

Synthetic fluids like Royal Purple MaxATF, Amsoil Signature Series, or Red Line D4 ATF are top choices. They resist heat better, maintain viscosity under stress, and reduce friction. Avoid generic or non-synthetic fluids. Always use the fluid type specified by your transmission manufacturer-even if you’re tuning. Mixing fluids can cause unpredictable clutch behavior.

Can I tune a transmission with a stock torque converter?

You can, but you’re limiting your results. Stock converters are designed for low horsepower and smoothness. Under 500 hp, they’re usually fine. But if you’re running 600+ hp or towing heavy loads, the converter will slip and overheat. A performance converter with a higher stall speed and better lockup control will make your tune more effective and protect the transmission. Don’t skip this if you’re serious about longevity.

Mark Brantner

November 4, 2025 AT 18:11so i just flashed my 6l80 with a $200 tune and now it shifts like a angry badger???

Franklin Hooper

November 5, 2025 AT 08:24Shift points aren't about power bands they're about hydraulic dynamics and torque vectoring efficiency. You're reducing the transmission's service life by ignoring the pressure gradient curves. The 6,500 RPM threshold isn't arbitrary-it's the point where the clutch pack's friction material begins to undergo microstructural fatigue. You're not tuning-you're gambling with cast iron.

saravana kumar

November 5, 2025 AT 08:44Bro you talking about 6L80 like it's a Ferrari engine. In India we fix transmission with hammer and prayer. You want longevity? Change fluid. That's it. No maps. No psi. Just clean fluid and don't ride the clutch. Why overcomplicate?

Tamil selvan

November 6, 2025 AT 09:12Thank you for this comprehensive and meticulously researched breakdown. It is imperative that we approach transmission tuning not as a performance enhancement exercise, but as a holistic maintenance protocol. The emphasis on fluid integrity, thermal regulation, and component health before any electronic intervention is not merely advisable-it is non-negotiable. I have personally witnessed three transmission failures in my community due to the reckless application of aftermarket tunes without baseline diagnostics. Please continue sharing such grounded, science-backed guidance.

Samar Omar

November 6, 2025 AT 22:18Let’s be honest-most of you are just chasing that ‘hard shift’ feeling like it’s some kind of dopamine hit. You think you’re a tuner? You’re just a guy with a laptop and a death wish. I’ve seen transmissions fail at 40k miles because someone cranked line pressure to 200 psi thinking it ‘felt sportier.’ The valve body doesn’t care how cool you think you are. It just wants to live. And if you don’t respect the hydraulic balance, it will die screaming. I once watched a 6L80 blow apart on a highway-shrapnel hit the rear axle. That’s not a tune. That’s a crime scene.

chioma okwara

November 7, 2025 AT 00:06you said 6500 rpm kills transmissions but what about the 2024 ford raptor with 700hp? they shift at 6800 all day long?? you dont know what ur talking about

Jess Ciro

November 7, 2025 AT 12:28They don’t want you to know this but every factory transmission has a hidden kill switch built in. The moment you tune it, the ECU starts logging your sins. They wait 18 months. Then-BAM. Transmission fails. Warranty denied. You get a letter saying ‘evidence of unauthorized calibration.’ They knew. They always knew. And they’re laughing. You think you’re smart? You’re just a data point in their profit model.

amber hopman

November 9, 2025 AT 06:20I’ve been running Royal Purple MaxATF in my 2020 Mustang for 3 years now-400hp, track days, daily driving. No slipping, no overheating. I change it every 30k and I use a transmission temp gauge wired to my phone. I also use the stock converter and it’s fine. You don’t need a $2k aftermarket unit if you’re smart about your tune. Just don’t ignore heat. That’s the silent killer.

Jim Sonntag

November 10, 2025 AT 00:44Look I get it. We all want our cars to feel like they’re gonna launch into orbit. But here’s the thing-my 2015 Silverado with 500hp and a tuned 6L80 has 210k miles on it. Fluid changed every 30k. Line pressure at 140 max. Lockup at 45mph. No drama. No smoke. No tears. The secret? Patience. Not power. You wanna be the guy with the 220k mile transmission? Be the guy who tunes for the long game. Not the guy who broke his transmission at 55k because he thought ‘firmer is better.’

Deepak Sungra

November 11, 2025 AT 16:38bro why you even care? i just bought a used truck with a bad transmission and i got it fixed for $800 with a used unit from junkyard. now it runs fine. you people spend hours on forums arguing about psi and torque curves. i just drive. and i’m happy. why you gotta make everything so complicated? life is short. let the transmission live or die on its own. i don’t even check the fluid.

Kate Tran

November 12, 2025 AT 05:38I used to think tuning was about power. Now I know it’s about respect. For the machine. For the math. For the people who’ll inherit the car after you.