Engine Anatomy: Understanding Your Car’s Power House

When working with Engine Anatomy, the layout and function of all internal parts that turn fuel into motion. Also known as engine structure, it is the foundation of any vehicle’s performance.

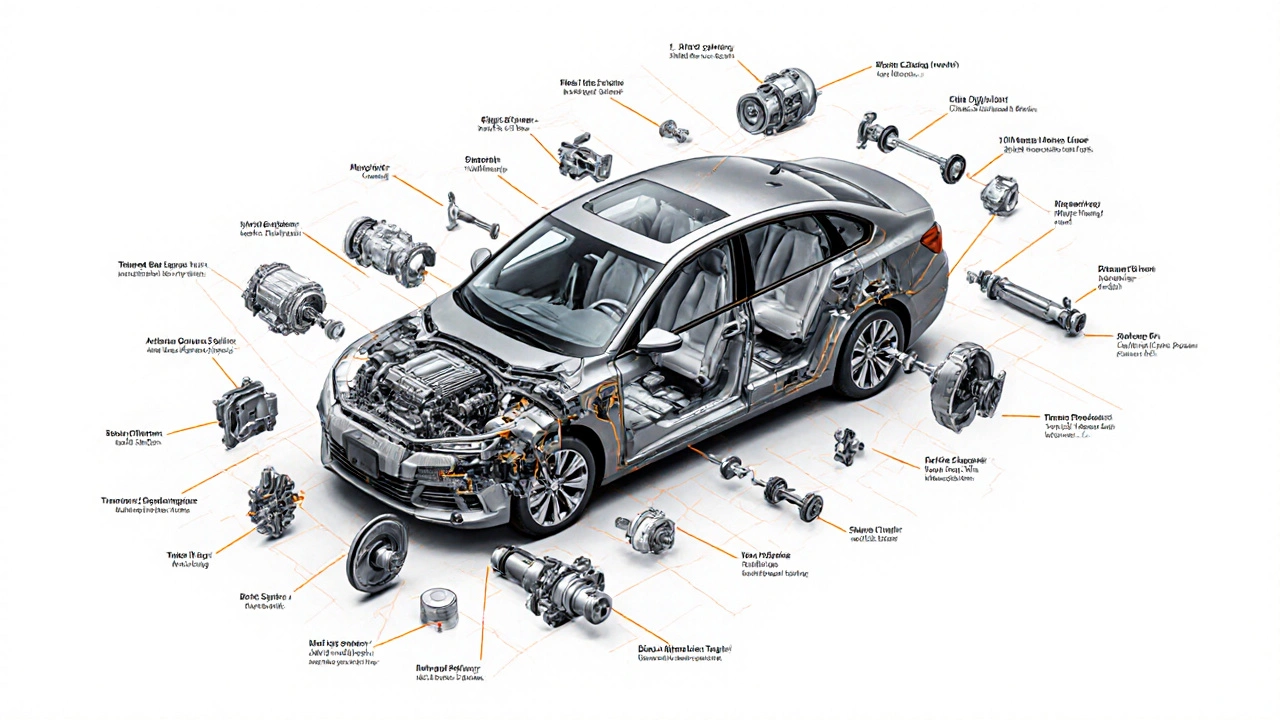

At its core, engine anatomy encompasses the Combustion Chamber, the sealed space where fuel mixes with air and ignites to create power. The chamber’s shape and volume directly influence efficiency, so engineers design it to promote even flame spread and minimize heat loss. A well‑shaped chamber works hand‑in‑hand with the fuel system, which meters the right amount of gasoline or diesel into the cylinder. That relationship forms a simple triple: *Engine anatomy* → *requires* → *combustion chamber*; *combustion chamber* → *is driven by* → *fuel system*. When the mixture ignites, the expanding gases push the pistons down, converting chemical energy into mechanical motion.

Beyond the chamber, the engine relies on a cooling system to keep temperatures in check. Water, coolant, and a thermostat circulate heat away, preventing warping of metal parts. Meanwhile, the exhaust system vents spent gases safely out of the vehicle, completing the power cycle. Understanding how these subsystems interact lets you spot problems early – a hot‑to‑touch radiator may signal a failing water pump, while a rough‑idle can point to a clogged injector. By grasping the big picture of engine anatomy, you’ll know what to listen for, what smells hint at trouble, and which components deserve regular attention.

Core Components You Should Know

The heart of the engine’s motion is the Pistons, metal cylinders that move up and down inside the engine block, converting expanding gas pressure into linear force. Each piston is attached to a connecting rod, which in turn links to the crankshaft – the component that turns linear motion into rotation. The Crankshaft, a forged steel shaft with offset throws that translate piston movement into the rotary power needed to turn the wheels is the engine’s primary output shaft. Together, pistons and crankshaft form another semantic triple: *Engine anatomy* → *includes* → *pistons*; *pistons* → *drive* → *crankshaft*. The camshaft adds timing precision by opening and closing valves at just the right moments. It works in sync with the crankshaft via a timing belt or chain, ensuring that air intake and exhaust outlets open and close in harmony with piston strokes. If the timing drifts, you’ll feel misfires, loss of power, or even engine damage. This illustrates a third triple: *Camshaft* → *controls* → *valve timing*; *valve timing* → *affects* → *engine performance*. Every moving part needs lubrication, so the oil pump circulates fresh oil through tight clearances, reducing friction and carrying heat away. The oil filter catches contaminants before they can scar bearings or cylinder walls. Regular oil changes keep this circulation smooth, extending the life of pistons, crankshaft bearings, and cam lobes alike.

Knowing how these pieces fit together does more than satisfy curiosity – it empowers you to make smarter maintenance choices. When you understand that worn pistons can cause loss of compression, or that a cracked crankshaft will throw the entire engine off balance, you can prioritize inspections, schedule repairs before a breakdown, and even negotiate better with mechanics.

Below you’ll find a curated collection of articles that dive deeper into each of these parts, compare OEM versus aftermarket options, and offer step‑by‑step guides on checking clearances, testing compression, and spotting early warning signs. Whether you’re a seasoned DIYer or just starting to get under the hood, the posts ahead will give you practical insight to keep your engine humming long after you read them.